Geometrically Frustrated Assemblies

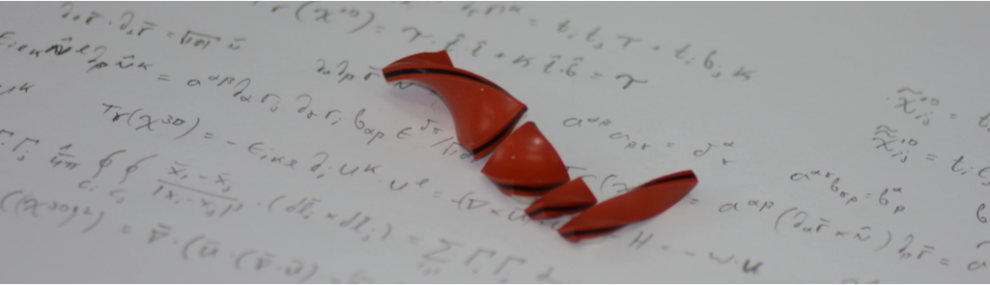

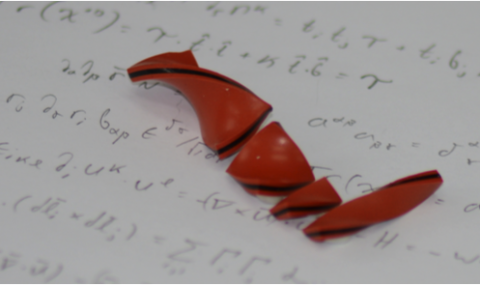

When manufacturing Lego pieces or the pieces of a jigsaw puzzle special care is taken to assure that the pieces would snugly fit next to one another without any need to deform. However, when tissue grows, a ductile material plastically deforms or a microstructure self-assembles there is no similar mechanism to assure that the different constituents would indeed perfectly fit next to one another. The misfit of the different part of the object gives rise to geometric frustation. The equilibrium configurations such strucutres assume compromoise between the mutually constradicting intrinsic tendencies. They are highly cooperative in nature and may give rise to highly complex structure and exotic response properties.